Production

About production

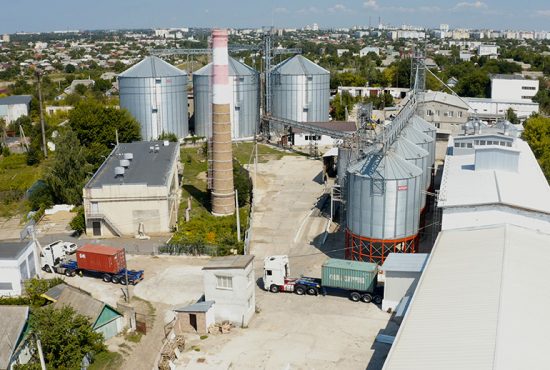

Our production capacities are fitted with high-performance advanced equipment and innovative systems of complex automation of technological processes manufactured by leading companies.

The modern production and technological laboratory carries out quality control-on both national and European standards. It is held at all the stages, starting from ground grain reception to the shipment of end products. The production process data allows making adjustments promptly and purposefully, determining end product quality.

Flour production process

Consists of the following steps:

Laboratory tests

Laboratory tests are perfected at each stage to determine the grain quality and improve flour characteristics

Grinding batch preparation

Is held within the mixing process of 4 and more various batches that aims to the grain quality improvement.

Grain cleaning and conditioning

Any dirt, mineral inclusions and admixtures of other plants seeds are removed by dry and wet methods from the grain mass.

Hydrothermal treatment

This stage creates an internal tension inside the grains, facilitating the separation of membrane covers.

Grain grinding stage

Repeated and Complex grinding commence, processing the flour of the required quality.

Vitaminization stage

Vitamins enrichment improves the quality of flour and is generated upon the request of the Customer.

Packing

An automatic stuffing line permits to pack our product in paper bags of 0.5 kg, 1, 2, 4, 5 kg, as well as in polypropylene bags of 25-50 kg.

Storage and supply

Are carried out in packages and in bulk.

Manufacturing equipment

Our mill complex is fully equipped with the latest technology and complies with all requirements, what allows to model production processes and compose the optimal grinding batches. The right choice of ground grain and advanced processing methods make it possible to produce custom-made flour with the corresponding functional properties. Important to note, that latest technologies for grain processing preserve the nutritional value and taste complexity of the product.

Thus, in the process of new product development, we created the flour brand Grand, which combines the highest quality and safety parameters.

Packing services

We provide packing, storage and supply services under the following terms:

In paper bags - 0.5 kg, 1 and 2 kg, 4 and 5 kg

In packages – in a finished product section

In bulk – at the flour bulk storage

As per Client’s request we are able to offer personalized brand logo bags.

Flour export

We strongly fulfill our contractual obligations and consider possible claims caused by the improper delivery of our products by transporting companies. A video recording was organized at our storage facilities, allowing us to monitor the loading process quality and facilitate the after-sale service including requests to file the claims.

Flour and bran are transported in 20 or 40 ft sea containers. Before the loading commence, container are being inspected on intactness, tightness, cleanliness and extraneous odors absence. When its suitability for loading is confirmed, the internal walls and floor are lined with cardboard paper, and a desiccant is placed inside to avoid condensation. That is essential for an intact and safe goods delivery and prevents the damage while transporting.

Our advantages

The buyer monitors his order and its status

Online order tracking

under development